In a world with an ever-growing focus on sustainable technologies, water-soluble printed circuit boards are immensely important. This innovative technology not only offers ecological benefits, but also revolutionizes the manufacturing and recycling of electronic products. Read on to learn more about the green technology of the British start-up Jiva Materials Ltd.

Why Water-Soluble Printed Circuit Boards?

Printed circuit boards are the central component of many electronic devices and often underestimated as a source of pollution. Especially because the electronics industry is known for its rapid turnover, it contributes significantly to the rise of electronic waste and thus growing environmental pollution.

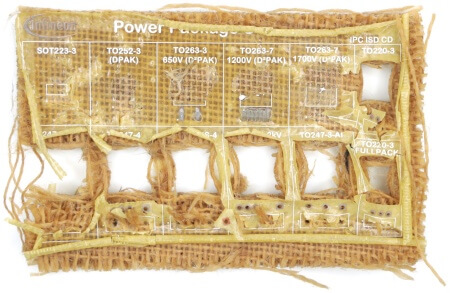

To respond to the growing awareness of green alternatives, economically viable solutions have to be found. That is why the revolutionary Soluboards mark a crucial turning point for the semiconductor industry and the entire technology world. Soluboards are an environmentally friendly alternative to conventional printed circuit boards, which are based on toxic chemicals. The production of conventional circuit boards often involves the use of aggressive chemicals such as etching agents and solder resists which are harmful to the environment and can pose health risks to personnel, whereas the green version consists of biodegradable natural fibers and a special polymer that is soluble in hot water.

This means that the water-soluble PCBs may completely be dissolved with hot water in a controlled environment without leaving any harmful residues. This enables the recovery of natural fibers, copper, and electronic components, which often contain valuable and expensive minerals. In many cases, even the electrical components obtained from the Soluboard circuit boards may be reused.

The Advantages of Water-Soluble Printed Circuit Boards

Figure 1: Intact Soluboard from Jiva Materials Ltd. Figure 2: The environmentally friendly PCB disintegrates or degrades in full contact with hot water. (Image source: Infineon)

The new circuit board technology promises an impressive reduction in the CO2 footprint of around 60%. This could save 10.5 kg of carbon and 620 g of plastic per square meter of printed circuit board. As already mentioned, Jiva Materials Ltd. relies on energy-saving materials such as natural fibers, plant-based PCB material, and a halogen-free polymer. This innovative composition not only allows for a more efficient production, but also significantly simplifies the recycling process. This means less environmental impact and a higher preservation of resources.

The inclusion of Soluboard in the product range of the leading semiconductor manufacturer Infineon Technologies underlines the potential of this technology. Andreas Kopp, Head of Product Management Discretes at Infineon, emphasizes the ecological and economic advantages of Soluboard. Jonathan Swanston, CEO of Jiva Materials Ltd., sees his product not only as a contribution to environmental protection but also as a way for companies to recover valuable metals more effectively [text source].

The benefits of water-soluble PCBs are not only environmental and recycling benefits but also health and safety benefits. For example, the use of water-soluble materials significantly reduces the risk of health hazards during the manufacturing and use of PCBs, resulting in a safer working environment.

Applications of Water-Soluble Printed Circuit Boards

Currently, environmentally friendly printed circuit boards are increasingly employed in consumer electronics and industry. However, Infineon is exploring the possibility of using the environmentally friendly material of soluboards for all its boards to make the electronics industry more sustainable. This is part of Infineon's commitment to implement the European Commission's "Green Deal" agenda. The aim is to achieve climate neutrality by 2050 and promote the circular economy to accelerate the ecologization of the EU economy.

Furthermore, Infineon has committed to collect and recycle electronic products responsibly and in accordance with the EU Waste Electrical and Electronic Equipment (WEEE) Directive. [Text source].

If in the future, all this is realized as planned, the PCB technology could be applied in a wide range of industries, including:

- Consumer electronics

- Industry

- Medical

- Automotive industry

- Aerospace

Future of Electronics Production

Water-soluble printed circuit boards will undoubtedly play a key role in the future of the electronics industry. They represent a groundbreaking innovation and offer a multitude of ecological and economic benefits. With their environmentally friendly production, the ease of use and versatility of application, they are helping to create a more sustainable future for the electronics industry.

With the increasing focus on environmental protection and sustainability, the demand for water-soluble PCBs is expected to keep growing. This green technology will therefore become increasingly important and consolidate its place as the green technology of tomorrow.

Content Information

Editor: RoodMicrotec GmbH

Source: The text is based on information from RoodMicrotec GmbH.

Copyright: All images, videos and audio files published in this article are subject to copyright. Reproduction in whole or in part is not permitted without the written permission of RoodMicrotec GmbH.

For further information or inquiries about a joint cooperation, please contact