Supply Chain Management – From the product idea to the final ASIC

Supply Chain Management – From the product idea to the final ASIC

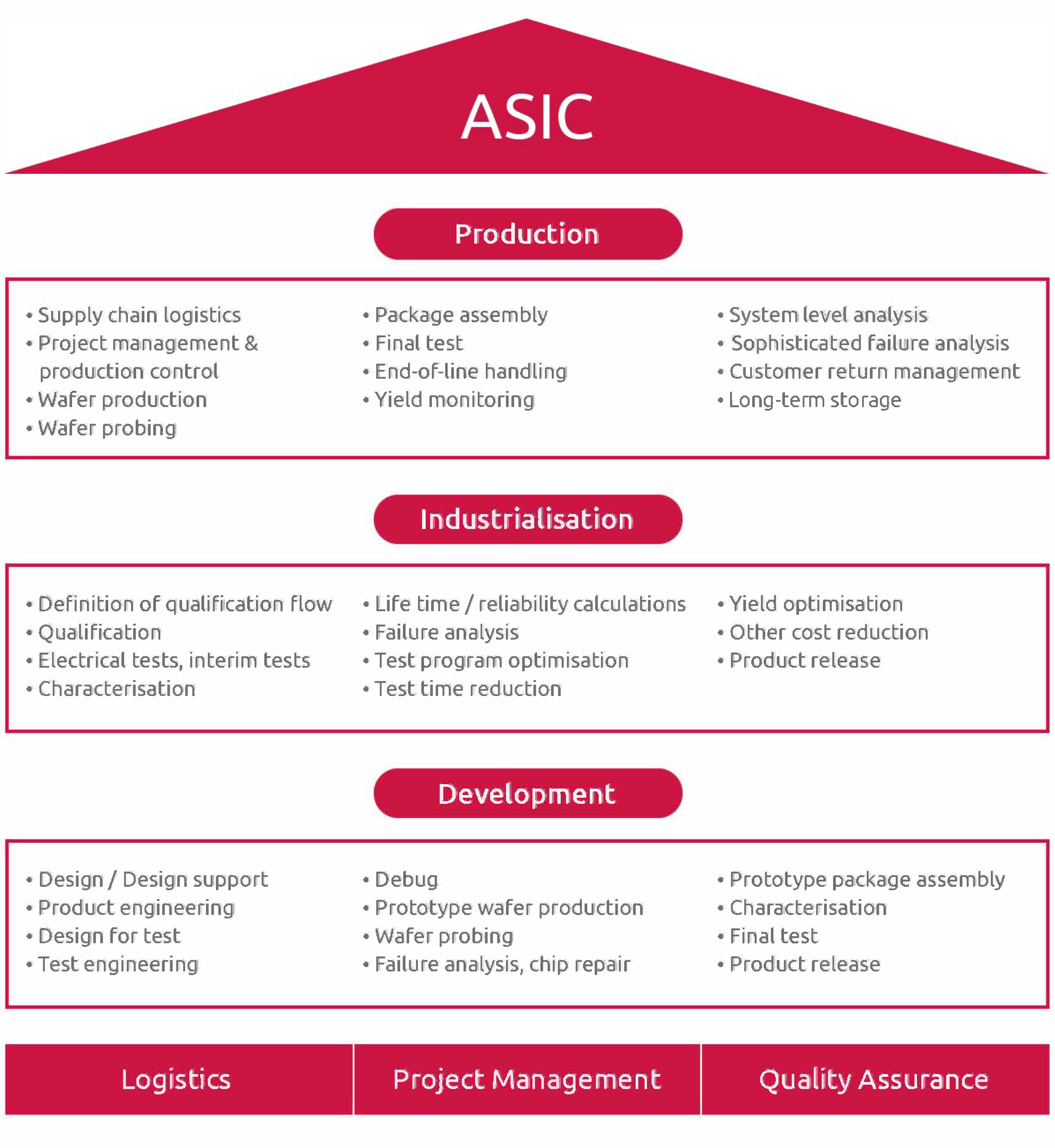

Overall there are three phases in ASIC projects – the development phase, the industrialisation phase and the production phase.

Our goal is to attend you competently in each phase of your ASIC project and to guarantee always only one contact person.

Development phase: designing and testing a prototype

In this phase, we work with you to design and create a prototype of your idea. Thereby, we collaborate with professional design houses and semiconductor manufacturers, short FABs, which translate your idea to integrated circuits and produces a first quantity of your specific chip, that will be developed into the first prototypes. Afterwards, various functional-, wafer- and component tests through to failure and material analysis methods play an important role. Only in this way your chip finally has the quality you need for your product. These tests are carried out in our in-house laboratories. We offer you the entire portfolio of climatic, mechanical, electrical and optoelectronic tests. The hardware and software will be developed by our experienced engineers in advance.

Industrialisation phase: preparing serial production

In the industrialisation phase we optimise the test environment in a permanent exchange of information with you, to keep the costs as low as possible. If the prototypes have been tested sufficiently, the first pilot series follows. Thereby, a so-called assembly house packages your chips. For this purpose, we use our contacts to professional assembly houses. If required, we can carry out various qualifications and environmental tests and issue certificates and independent expert reports, for example for the in the automotive sector established qualification standards AEC Q 100 and AEC Q 101 or the industry standard JESD47. At the end of the industrialisation phase we have proved the series maturity for all wafer tests, final tests and end-of-line tests. Qualified components are therefore available for this phase.

Production phase: setting serial production

The production phase is about to produce and deliver the chips which have formerly been produced in small series and qualified, as series parts. We also take care of all coordination tasks including the worldwide logistics. We are happy to be your point of contact in the event of unexpected failures or customer returns (RMA). We can check your production facilities for electrostatic discharge (ESD) risks and make suggestions for optimization.

Inclusive quality assurance, project management and worldwide logistics

With us as general partner you have the advantage that you get competent support in each of the three phases of an ASIC project. Additionally, we provide a broad project management: we support you for example with extensive automotive projects like the complex production approval process PPAP or the production quality forecast APQP. We are able to react flexibly to your requirements and also to project changes. Quality assurance is our ultimate ambition. Our in-house failure analysis offers the best conditions to react competently and quickly to noticeable problems. Furthermore, we take care of the entire logistics – worldwide.

RoodMicrotec as reliable partner with industry expertise

RoodMicrotec as reliable partner with industry expertise

With our Supply Chain Management we offer straightforward processes and turnkey solutions – and this with many years of industry expertise. Our know-how especially in the sectors industrial, automotive, healthcare and high reliability (HiRel) / aerospace we use to offer you the best support. You are searching for a competent partner for your ASIC project? If so, you are right here. It is up to you to decide whether you want the complete package or partial quantities.

We are looking forward to your contacting.