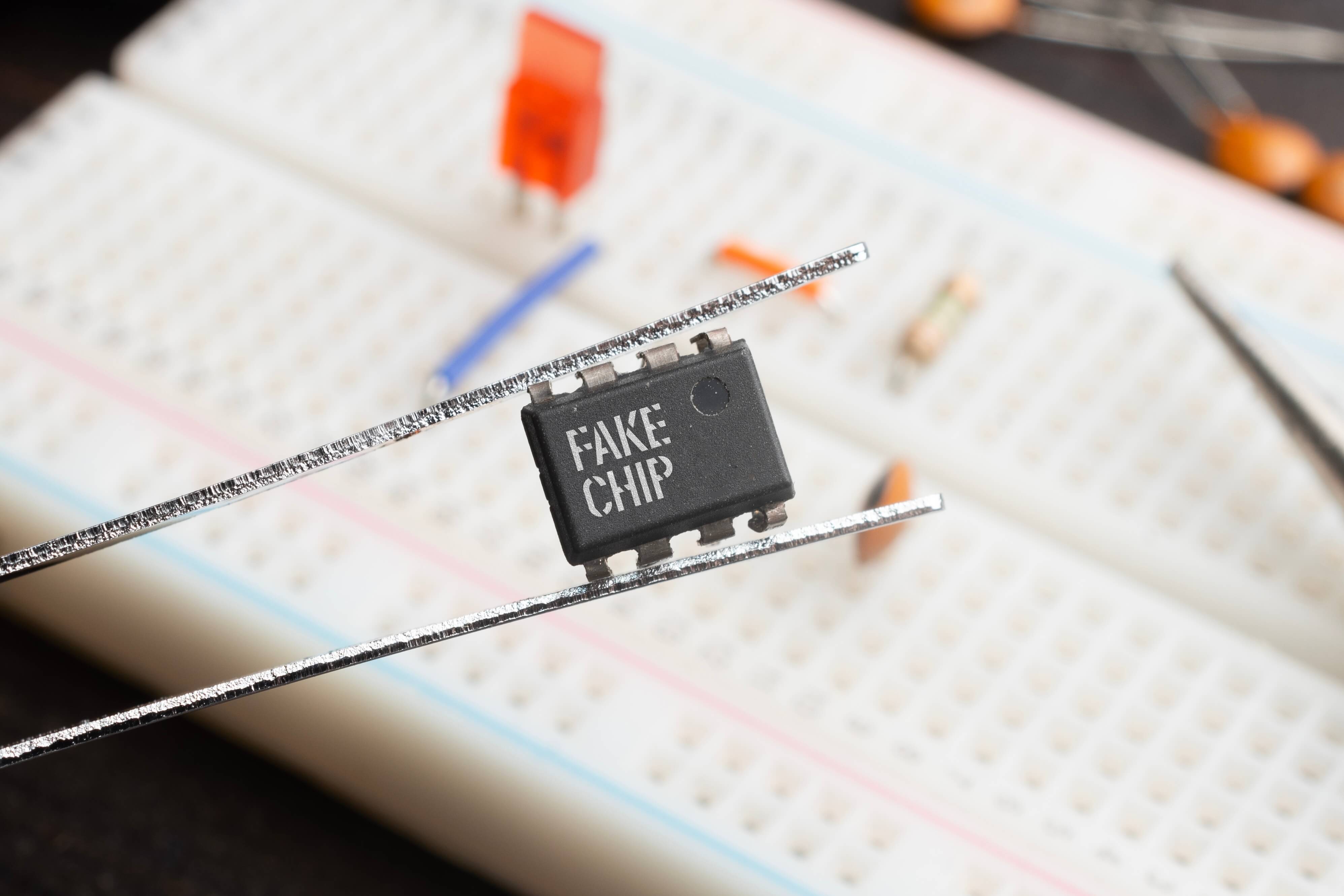

Counterfeit components that do not meet the specified standards could impair the functionality of end products.

Due to the ongoing shortage of components on the global market, many companies procure electronic components via brokers. They are often forced to tap new sources of supply, sometimes with an unknown background, and cannot just rely on existing business relationships. As a consequence, a delivery of counterfeit goods may not be ruled out.

Especially in these times of shortage, the proportion of counterfeit goods has increased significantly and thus consequently led to a boost in the need for originality tests. With the testing, companies want to ensure that only original parts are used in their products. Very often, the price and the quick availability of an assessment are important criteria. For this reason, RoodMicrotec GmbH offers a swift analysis, which checks important criteria for the detection of counterfeits from only five working days onwards.

Quality Guarantee for Electronic Products

Special care has to be taken with reeled goods in particular. Based on years of experience, RoodMicrotec knows that there are often original parts at the beginning and the end encircling counterfeits in the middle. In order to take account of this, a process has been developed in which individual components can be removed from the middle without causing problems or interruptions during the subsequent assembly. However, these quick tests are not sufficient for handlers of safety-relevant systems or when extreme reliability is required. Pushed by the American aerospace industry, the SAE (Society of Automotive Engineers) published the standard AS6081A ("Counterfeit Electrical, Electronic, and Electromechanical (EEE) Parts: Avoidance, Detection, Mitigation, and Disposition - Independent Distribution"). This comprises a much more extensive investigation. In addition to further tests, also the number of examined components is significantly higher. RoodMicrotec offers this inspection program in compliance with AS6081A and it should be mentioned that currently, it is the only German company to offer this test as an accredited procedure according to DIN EN ISO/IEC 17025:2018 - even in the latest revision A of the standard, published on 21st April 2023.

Authenticity Verification of Components

When checking the originality of broker goods, it is convenient to have a so-called golden device for the analysis, i.e. an original part that is available as a reference sample. This makes it much easier to detect counterfeits. Thus, the user should take logistical measures to create a pool of original parts.

A few years ago, it was possible to detect deviations in the lead frame between the tested goods and the golden device. This was done by X-ray analysis, which could identify a counterfeit component with almost certainty. Nowadays, this has changed due to limited resources in the back end. Manufacturers are forced to have components packed in different assembly lines, which may create differences in the lead frame layout. Moreover, there can even be variations in the bonding wire material, as the golden devices usually have an older date code. Thus, it cannot be excluded that, e.g., a switch from a gold to a copper bonding wire has been made, resulting in different materials to be examined. It is therefore immensely important to physically examine the components and additionally carry out comparisons with the data sheets, as they often contain important information on possible deviations from the manufacturer's specifications.

Another example for the importance of authenticity tests are used brokerage goods. In addition to counterfeit goods, samples with an original semiconductor chip are often submitted for examination. However, as these may be recycled parts, i.e. components that have already been in use and were then unsoldered and refurbished, special caution is required. Furthermore, components may be repainted and relabeled and although these are original products from the manufacturer, the new labeling falsely turns them into variants with supposedly better properties, e.g. in terms of electrics or reliability. Besides checking for originality, it has to be taken into account that, apart from the suitability, also the processability of the component has to be ensured. In this respect, it is worth considering to carry out a solderability test to make sure that the components will not cause any problems in assembly production later on.

As a conclusion, it should be noted that there is no 100 percent protection against counterfeit components. In the end, it is merely the question how well the original parts are copied. However, the good news is that a reliable statement regarding originality can be made with a high degree of probability. The majority of counterfeits can easily be identified and distinguished from original parts.

Summary

The fight against counterfeit components requires a close cooperation between manufacturers, distributors, authorities, and the entire electronics industry to ensure the safety and quality of electronic products.

Are you interested in our failure analysis test services or a technology assessment? Contact us

Content Information

Editor: RoodMicrotec GmbH

Source: The text is based on information from RoodMicrotec GmbH.

Copyright: All images, videos and audio files published in this article are subject to copyright. Reproduction in whole or in part is not permitted without the written permission of RoodMicrotec GmbH.

For further information or inquiries about a joint cooperation, please contact